| HOME

|

|||||||||||

Horizontal Autoclave with One-touch Lid Interlock System

Full-automatic Autoclave with Drying Function

HRH

HRH

HRH-110

■ Features & Functions

Clean drying without contamination

After sterilization, drying is performed with the lid closed.

Clean drying can be carried out without worry of contamination.

After sterilization, drying is performed with the lid closed.

Clean drying can be carried out without worry of contamination.

Pre-vacuum air removal using a vacuum pump

A vacuum pump is installed to remove residual air with vacuum.

This is effective when sterilizing objects put in containers or bags from which air is difficult to escape.

A vacuum pump is installed to remove residual air with vacuum.

This is effective when sterilizing objects put in containers or bags from which air is difficult to escape.

Electro-mechanical lid lock system

The lid can be opened and closed easily and reliably with the one - touch lever.

A pressure seal method is used as a safety measure.

The lid can be opened and closed easily and reliably with the one - touch lever.

A pressure seal method is used as a safety measure.

Dual interlock mechanism

The lid is locked by dually detecting the chamber pressure and chamber temperature during operation.

The lock state is maintained even if an operation is manually interrupted.

The lid is locked by dually detecting the chamber pressure and chamber temperature during operation.

The lock state is maintained even if an operation is manually interrupted.

Dual detection system for residual air

The residual air which may cause sterilization failure is dually detected to always maintain the appropriate sterilization conditions for loads. ※The residual air is detected at the process before pressurization (during operation of an air removal timer) and at the process of pressurization air exhaust.

The residual air which may cause sterilization failure is dually detected to always maintain the appropriate sterilization conditions for loads. ※The residual air is detected at the process before pressurization (during operation of an air removal timer) and at the process of pressurization air exhaust.

Power saving design

By reducing power consumption, we can provide more ecological and economical devices. (Its power consumption is approximately 2 / 3, compared with our former autoclave.)

By reducing power consumption, we can provide more ecological and economical devices. (Its power consumption is approximately 2 / 3, compared with our former autoclave.)

Required utilities

※Ask us for details.

※Ask us for details.

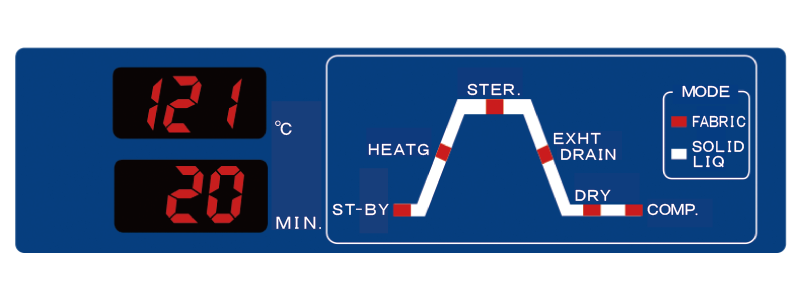

■ Display panel

|

■ Operation cycle of each mode

| MODE 1 : FABRIC |  | Vacuum air removal |  | Heating |  | Sterilization |  | Exhaust, Drainage |  | Drying | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ●Main applications: Sterilization of gauze, cloths that require drying after sterilization. | ||||||||||||

| MODE 2 : SOLID |  | Vacuum air removal |  | Heating |  | Sterilization |  | Exhaust, Drainage | ||||

| ●Main applications: Sterilization of instruments made of glass, ceramic, metal or rubber that can withstand high temperature, high pressure steam and rapid pressure reduction during exhaust. | ||||||||||||

| MODE3 : LIQUID |  | Heating |  | Sterilization |  | Exhaust | ||||||

| ●Main applications: Sterilization of liquid, which can withstand high temperature and high pressure steam such as water, culture medium, reagent, reagent solution, liquid medicine, etc., and sterilization of waste using sterilization bag.

| ||||||||||||

| MODE4 : Additional drying |  | Drying | ||||||||||

| ●Main applications: Additional drying of gauze, cloths | ||||||||||||

■ Options for upgrading a system

| Floating sensor | Recorder | Printer | Automatic water supply from tank |

|---|---|---|---|

|

|

|

|

| A sterilization timer operates after the temperature of the materials to be sterilzed reaches the set temperature. | (Image is a chart type recorder.) ・Chart type recorder: 6-point dotting ・Hybrid recorder: 8-point dotting ※Chart width: 100 mm ※Class 2 T-type thermocouple included |

※Thermal print type | Manual water supply to the chamber becomes unnecessary. |

■ Option

| Square wire basket, stainless steel | Plate-bottomed basket, stainless steel | Round dressing drumstainless steel |

|---|---|---|

|

|

|

| W380 x D280 x H240 mm | W380 x D280 x H240 mm | [Small] φ170 x H120 mm [Medium] φ200 x H150 mm [Large] φ260 x H180 mm |

■ Specifications

| Product name | HICLAVE HRH Autoclave with a vacuum pump | |

|---|---|---|

| Model | HRH-110 | |

| Effective capacity | 110 L | |

| Chamber size (φ x H mm) | 420 x 795 | |

| Operation mode | 4 modes (FABRIC, SOLID, LIQUID, ADDITIONAL DRYING) | |

| Sterilization temperature setting range | 105℃ - 135℃ Variable | |

| Lid lock | 97℃, fixed | |

| Time setting range | Sterilization | 1 min - 60 min, Remaining time is displayed |

| Drying | 1 min - 120 min, Remaining time is displayed | |

| Exhaust setting | 3 levels (Without exhaust, Fine exhaust, Small amount of exhaust) | |

| Drying method | Vacuum drying using a water seal vacuum pump and heating of the outside of the chamber | |

| Maximum working pressure | 0.255MPa | |

| Thermometer | Digital display 5℃ - 137℃ | |

| Pressure gauge | Analog display -0.1MPa - 0.4MPa | |

| Safety devices | Pressure safety valve, Earth leakage breaker, Low water cut off device, Earth leakage breaker, Vacuum pump breaker | |

| Alarms, error display | Low water heating, Temperature sensor wire disconnection, Over-temperature, Over-cool, Over-pressure, Abnormality in lid opening / closing lever lock, Lack of water for vacuum pump bottle | |

| Outside dimensions (W x D x H mm) | 690 x 1150 x 1385 | |

| Weight (Approximately) | 174 kg | |

| Pressure vessel category | Small sized pressure vessel | |

| Chamber material | Stainless steel (SUS304) | |

| Power supply | AC 220V / 230V / 240V, 50Hz / 60 Hz, Single-phase (Please specify the voltage when ordering.) | |

| Required power supply facility | 3.2kW | |

| Supplied accessories | Drain hose, Water supply hose, Wire shelf, Level vial | |

※Specifications and appearance are subject to change without notice due to continuous product improvement.