| HOME

|

|||||||||||

Retort foods can be developed and sold at low cost.

More desirable food safety management can be performed by means of F-value control.

More desirable food safety management can be performed by means of F-value control.

Compact Retort Cooker with F-value control

HLM-36EF

HLM-36EF

HLM-36EF

■ Features & Functions

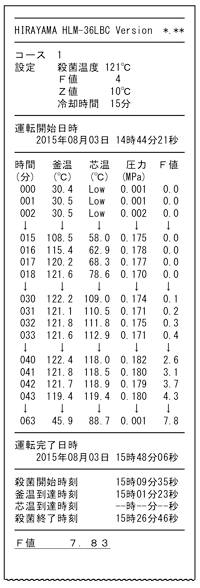

F-value control

F-value that is important for the retort sterilization is calclulated and controlled. You can safely make the retort food of your choice with simple settings.

F-value that is important for the retort sterilization is calclulated and controlled. You can safely make the retort food of your choice with simple settings.

Core temperature sensor

The internal temperature of the food is measured with a core temperature sensor, and the F-value is calculated and displayed. In MODE 1, when the temperature of a core temperature sensor reaches the target F value, the sterilization (cooking) stage is finished and the stage proceeds to the cooling stage. It is possible to print and record the data by connecting an optional printer.

The internal temperature of the food is measured with a core temperature sensor, and the F-value is calculated and displayed. In MODE 1, when the temperature of a core temperature sensor reaches the target F value, the sterilization (cooking) stage is finished and the stage proceeds to the cooling stage. It is possible to print and record the data by connecting an optional printer.

Pressure control method

High temperature and high pressure sterilization is performed by gradually raising the chamber temperature and pressure. This is effective for preventing damage to aluminum packs or film packs for retort foods.

High temperature and high pressure sterilization is performed by gradually raising the chamber temperature and pressure. This is effective for preventing damage to aluminum packs or film packs for retort foods.

A cooling device that can prevent damage to containers

Cooling water is sprayed while pressurizing the chamber with air in order to prevent rapid pressure change due to sudden condensation of vapor in the chamber during shower cooling. The seal portion of a bottle or container is prevented from being damaged.

Cooling water is sprayed while pressurizing the chamber with air in order to prevent rapid pressure change due to sudden condensation of vapor in the chamber during shower cooling. The seal portion of a bottle or container is prevented from being damaged.

Automatic operation

All stages from water supply, pressurization, sterilization (disinfection) to cooling are performed automatically.

All stages from water supply, pressurization, sterilization (disinfection) to cooling are performed automatically.

Compact body made of stainless steel

A stainless steel body that is clean and excellent in corrosion resistance is used. Sapce-saving compact autoclave.

A stainless steel body that is clean and excellent in corrosion resistance is used. Sapce-saving compact autoclave.

Equipped with external output terminal as standard

As a printer output connector is equipped as standard, it is easy to output data.

As a printer output connector is equipped as standard, it is easy to output data.

Electro-mechanical lid lock system Ⅱ

The electric clamp lid is employed. locking / unlocking of the lid can be performed simply by pressing a button. The chamber opening is widely opened for easy loading and unloading.

The electric clamp lid is employed. locking / unlocking of the lid can be performed simply by pressing a button. The chamber opening is widely opened for easy loading and unloading.

Dual interlock mechanism

The lid is locked by detecting chamber pressure and temperature during sterilization. Even if an operation is interrupted manually, the lock state is maintained.

The lid is locked by detecting chamber pressure and temperature during sterilization. Even if an operation is interrupted manually, the lock state is maintained.

Sufficient treatment capacity (Loading capacity)

| Pouch volume | Maximum loading capacity |

|---|---|

| 250 ml - 300 ml | 30 P - 45 P |

| 400 ml - 500 ml | 15 P - 30 P |

| 1000 ml | 15 P |

| (For reference) |

|

Programmable auto - start function

An operation starts at the set time.

An operation starts at the set time.

Memory function

Set contents can be registered for each mode.

Set contents can be registered for each mode.

Recommended for food production in small lots

Useful for new entry into a new business.

Manufactuering the original food products of local specialty.

Food development and sample food production in a food manufacturer.

Processing and cooking of surplus food materials.

Manufacturing preservation foods.

Useful for new entry into a new business.

Manufactuering the original food products of local specialty.

Food development and sample food production in a food manufacturer.

Processing and cooking of surplus food materials.

Manufacturing preservation foods.

Installation requirements are minimal and maintenance cost is low

It can be installed simply by providing power source and water supply / drainage. See the following installation requirements. Qualification for handling boilers or pressure vessels is unnecessary. (It is necessary for users to inspect it once per year.)

It can be installed simply by providing power source and water supply / drainage. See the following installation requirements. Qualification for handling boilers or pressure vessels is unnecessary. (It is necessary for users to inspect it once per year.)

Installation requirements

・Power supply: AC200V 25A or more

・Water supply: Water supply of 0.23MPa to 0.40MPa, Flow rate of 6 L / min. or more

・Drainage: We recommend steel pipes for high temperature and high pressure drainage.

※Ask us for details.

・Power supply: AC200V 25A or more

・Water supply: Water supply of 0.23MPa to 0.40MPa, Flow rate of 6 L / min. or more

・Drainage: We recommend steel pipes for high temperature and high pressure drainage.

※Ask us for details.

■ Cooking examples and users

| Various original foods can be made. Examples of foods cooked and sold using this retort cooker are as shown below. |

||||

|

|

|

|

|

| Indian curry in aluminum bag | Boiled pork in aluminum bag | Maitake mush-room rice basein transparent bag | Japanese Local cuisine called KOZUYU in transparent bag | Boiled seafood (Fish) in transparent bag |

| (The photo above is just an example of food cooked with this retort cooker.) | ||||

| Various other foods are also made using this retort cooker. |

||||

| Curry in aluminum bag | Stew in aluminum bag | Soup in aluminum bag | Boiled meat in aluminum bag | Boiled vegetables in aluminum bag |

| Steamed vegetables in transparent bag | Rice base in transparent bag | Soup in aluminum bag or transparent bag | Boiled seafood in transparent bag | Boiled seafood in soy source packed in transparent bag |

| Various seafood paste in can | Various curry paste in can | |||

| Retort cooker users | ||||||||||

| Agriculture, Fishery | Manufacturing industry(Food) | Manufacturing industry(Others) | Accomodation business, Restaurant |

Medical, Welfare, School | ||||||

| Business Category |

Agriculture Livestock industry Fishery Government offices related to the above |

Agriculture and livestock processing Fishery processing industry Side dish manufacturing industry Seasoning manufacturing industry Confectionery industry Central kitchen |

Packaging material manufacturing industry | Hotel Restaurant |

Hospital food manufacturing industry Welfare care food manufacturing industry Lunch center University Vocational school |

|||||

| Application | Store sales Mail order (online sales) Food loss countermeasure |

Food development Sample test Small lot production Food loss countermeasure |

Product development Endurance test |

Store sales Mail order (online sales) Food loss countermeasure |

Food development Preserved food production Food loss countermeasure Cooking practice |

|||||

| When selling the sterilized food, we recommend the model with F-value control (HLM-36EF). | ||||||||||

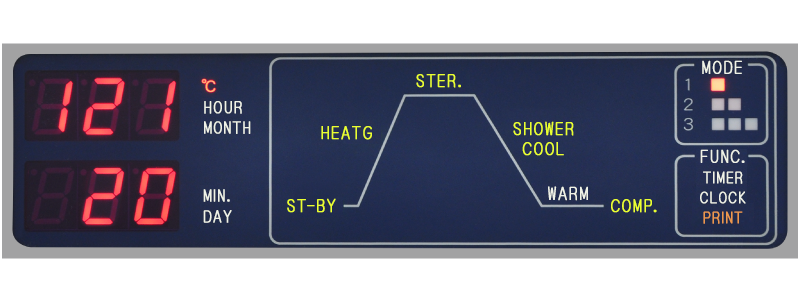

■ Display panel

|

■ Operation cycle of each mode

| MODE 1:Cooking (F-value control) |  | Automatic water supply |  | Heating Pressurization |  | Sterilization (Pressure cooking) |  | Shower cooling |  | Drainage |

|---|---|---|---|---|---|---|---|---|---|---|

| MODE 2:Cooking (Time control) |  | Automatic water supply |  | Heating Pressurization |  | Sterilization (Pressure cooking) |  | Shower cooling |  | Drainage |

| MODE 3:Cooking (Time control) |  | Automatic water supply |  | Heating Pressurization |  | Sterilization (Pressure cooking) |  | Shower cooling |  | Drainage |

■ Options for upgrading a system

| Printer |

|---|

|

| Data recorder (Thermal recording type) |

■ Options

| Round wire basket, stainless steel | Sterilization bucket, stainless steel | Tray, stainless steel |

|---|---|---|

|

|

|

| φ330 x H195 mm φ330 x H270 mm |

φ330 x H270 mm |

[Tray38] φ320 x H38 mm / (15 sets) [Tray48] φ320 x H48 mm / (12 sets) |

■ Specifications

| Product name | Compact Retort Cooker with F-Value Control | |

|---|---|---|

| Model | HLM-36EF | |

| Effective capacity | 63 L | |

| Chamber size (φ x H mm) | 360 x 620 | |

| Operation mode | 3 modes (MODE 1: Sterilization with F-value control, MODE 2 and 3: Time controlled sterilization) | |

| Sterilization temperature setting range | MODE 1: 100℃ - 125℃, MODE 2 and 3: 70℃ - 125℃, Variable | |

| Lid lock temperature | 97℃ fixed | |

| Time setting range | F-value control sterilization | MODE 1: 1 min - 99 min, Addition display system |

| Sterilization | MODE 2 and 3: 1min - 250 min, Reamining time is displayed | |

| Cooling | 10 min - 250 min, Reamining time is displayed | |

| Z-value setting | 10℃ fixed (Z-vlaue setting with OP, 5℃ - 20℃ Variable) | |

| Pressurizing force | 30kPa - 100kPa | |

| Maximum working pressure | 0.235MPa | |

| Thermometer | For chamber temperature: Digital display 5℃ - 129℃ For core temperature:Digital display 45℃ - 129℃ | |

| Pressure gauge | Analog display, 0MPa - 0.4MPa | |

| Safety devices | Pressure safety valve, Earth leakage and overcurent breaker, Low water cut off device | |

| Alarms and error display | Low water heating, Temperature sensor wire disconnection, Over-temperature, Over-pressure, Lid lock abnomality | |

| Outside dimensions (WxDxH mm) | 602 x 679 x 1064 | |

| Weight (Approximate) | 120 kg | |

| Pressure vessel category | Small sized pressure vessel | |

| Chamber material | Stainless steel (SUS304) | |

| Power supply | AC200V, 50Hz / 60Hz (Single Phase) | |

| Required power facility | 5.0kW | |

| Power connection | Ring terminal | |

| Supplied accessories | Adapter for pack (5), Packing for pack (100), Gasket for adapter (5), Stainless steel wire basket (3), Bottom plate (1) | |

※Specifications and appearance are subject to change without notice due to continuous product improvement.